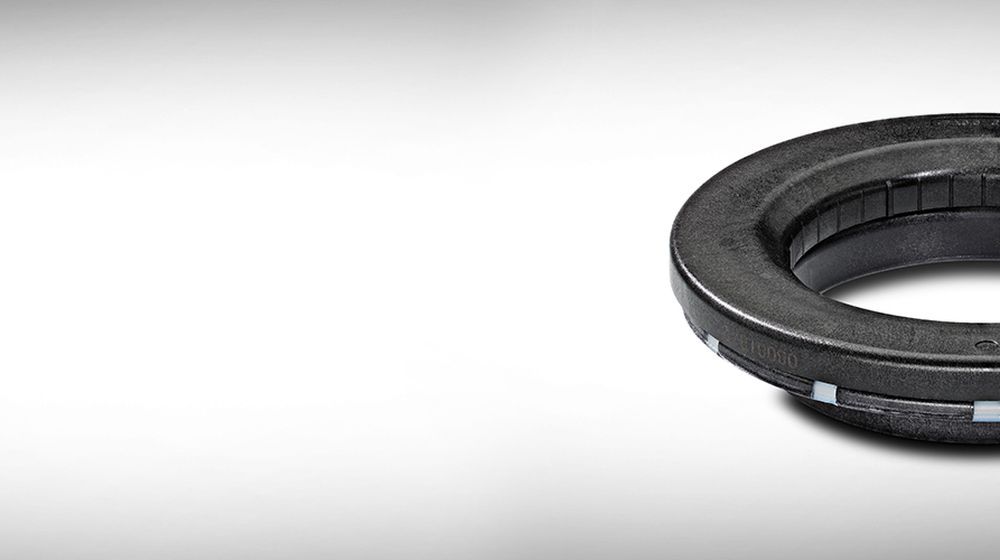

ROLLAX STRUT BEARING

Precise Steering Movements With Minimum Noise

Small content- Big effects

The new suspension strut bearing from Rollax GmbH enables precise steering movements with minimum noise development.

Suspension strut bearings are part of the damping system and are subjected to massive forces. They must regularly withstand many times the weight of the vehicle. They are constantly exposed to dirt and – especially in the winter months – road salt. Despite all these harsh conditions, the bearing must perform its service safely in all situations and allow precise and smooth steering movements. If possible, for the entire life of the vehicle.

Rollax, a leader in the development and production of ball bearings for almost 50 years, meets these high challenges with a specially developed strut bearing. In addition to basic robustness, the lowest possible weight and the smallest possible component size are important. With the growing focus on e-mobility, the noise factor is becoming an increasingly important priority. In contrast to conventional combustion engines, electric motors have a significantly reduced operating noise level.

Teamwork Was the Key to Success

These demanding requirements could only be met in cooperation with the project partners involved. Close coordination and a constant exchange between the component manufacturer, Rollax GmbH, the injection moulder, Denk Kunststofftechnik from Gevelsberg and the material suppliers were necessary.

Image dimensions not found

Change image or reupload it

AKRO-PLASTIC supplies the plastic compounds for the strut bearing. These had to be very robust, insensitive to dirt and have a high dimensional stability. In combination with metal inserts and a sealing component, the plastic material became the lower part of the shock absorber bearing in a 3K process.

A further challenge was the worldwide shortage of polyamide 6.6, which dominated the plastics market right at the start of the project. Here, AKRO-PLASTIC was able to develop alternative products based on PA 6 together with Rollax GmbH. For the previously used PA 6.6 GF 25, a PA 6 GF 35 was used. The PA 6.6 GF 30 was replaced by PA 6 GF 50.

Image dimensions not found

Change image or reupload it

These two materials, AKROMID® B3 GF 35 1 schwarz (2486) and AKROMID® B3 GF 50 1 schwarz (20008), were successfully sampled and after intensive tests, released by the OEM for serial production. Due to the moderate increase of the glass fibre content, the necessary requirements of the components could be achieved, and the slightly higher water absorption of PA 6 was kept under control.

The processing parameters as well as the process windows only had to be slightly adjusted for this change. AKRO-PLASTIC was able to carry out the small adjustments quickly together with the project partners by means of application-technical consulting. AKRO-PLASTICs application engineering team consulted the project partners to quickly carry out the necessary adjustments.

Our project partners

The perfect Compound for every application

Discover the perfect compound for your application in our COMPOUND EXPLORER.