SAFETY LOCK

)

Plasma-SealTight®

Plasma-SealTight® Safety Lock for Safety Doors

Together with the Wuppertal experts (K.A. Schmersal GmbH & Co. KG) for safety switching devices and safety interlocks and Kegelmann Technik GmbH, we present the Interlock AZM300. A safety lock device which has been produced with the help of Plasma SealTight® (PST) technology. Plasmatreat GmbH has developed the PST process to bond metals with plastic. AKRO-PLASTIC has developed a plastic compound AKROMID® B3 GF30 1 PST which shows outstanding mechanical performance when bonding it to metals with the PST technology. This new process provides a significant mechanical and cost improvement when producing hybrid plastic-metal components and can be integrated into series production lines.

Used on safety doors, this interlock AZM300 features a metal bracket integrated into a plastic housing. The bracket engages with an interlock cross-head to ensure that safety doors are securely closed. A reliable, firm bond between the metal bracket and plastic housing is crucial to produce a high-quality, mechanically resistant joint between the dissimilar materials plastic and metal.

The Plasma-SealTight® process developed by Plasmatreat and AKRO-PLASTIC, offers a completely new approach to the production of metall/plastic hybrid parts. In this new industrial solution, the plastic compound formula, the process parameters, and the composition of a plasma-polymer seal layer created under atmospheric pressure were matched to one another in such a way that they would create a durable, ultra strong and media-tight bond in the component.

Image dimensions not found

Change image or reupload it

Existing Solution

Metal bracket is fastened with screws and a backing metal plate on the backside of the plastic housing.

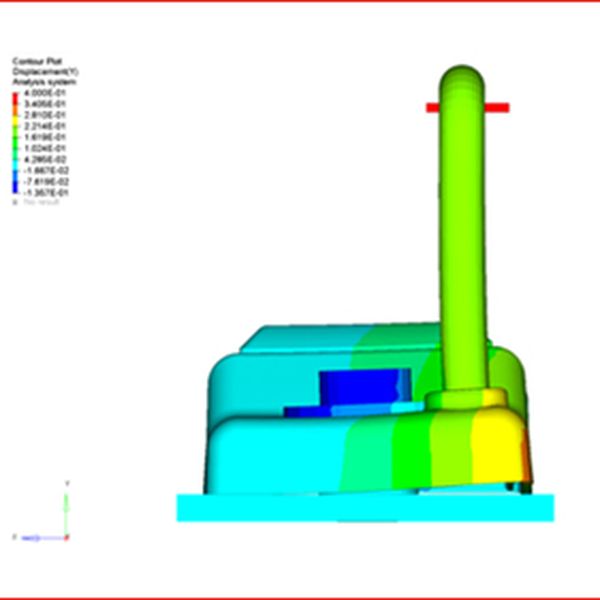

Calculation of the deformation with load introduction (existing solution no additional ribs added yet).

Image dimensions not found

Change image or reupload it

Plasma-SealTight® Solution

Metal bracket without thread (no undercuts) is coated with the PST technology and overmoulded. No assembly work and reduction of fixing components. Redesign of the plastic housing with ribs on the backside, in order to withstand the mechanical load of the metal bracket. Redesign and FEM Simulation performed by M.TEC.

Deformation with added ribs improved by 22 %: Calculation of the deformation with load introduction additional ribs added on the backside of plastic housing.

Image dimensions not found

Change image or reupload it

The Advantage of the New Process

The advantage of the new process is that it not only achieves better product quality, but also a reliable, reproducible, cost-efficient production process with the added bonus of respecting the environment.

Advantages of the safety lock AZM300

• Product safety due to chemical adhesion between metal and AKROMID® B3 GF 30 1 PST

• Material: AKROMID® GF 30 1 PST black (6647)

• AZM300 – Safety lock, operating principle with rotary shaft

The Project Partners

Disclaimer: All specifications and information given on this website are based on our current knowledge and experience. A legally binding promise of certain characteristics or suitability for a concrete individual case cannot be derived from this information. The information supplied here is not intended to release processors and users from the responsibility of carrying out their own tests and inspections in each concrete individual case. AKROMID®, AKROLEN®, AKROLOY®, AKROTEK®, ICX®, PRECITE® and DIA(hr)LOG® are registered trademarks of AKRO-PLASTIC GmbH.