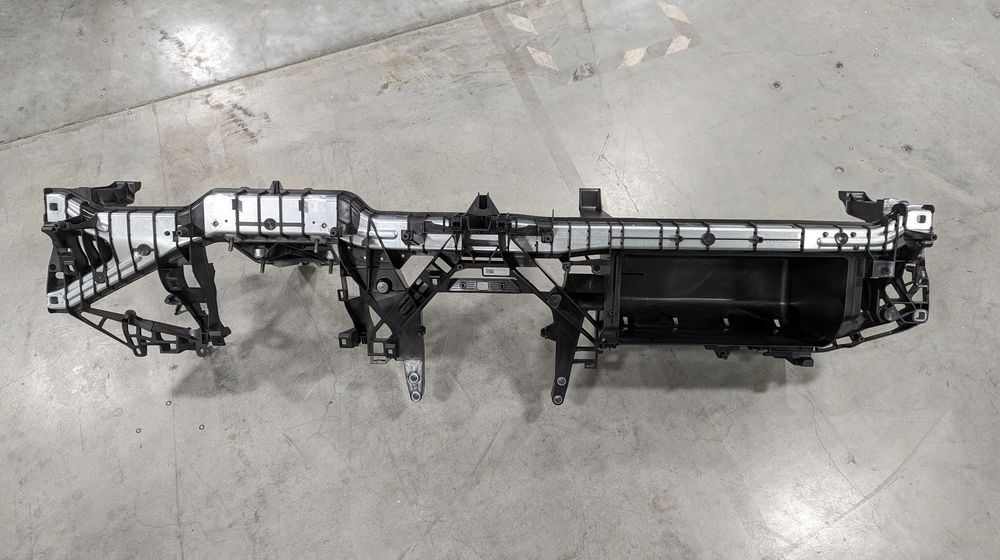

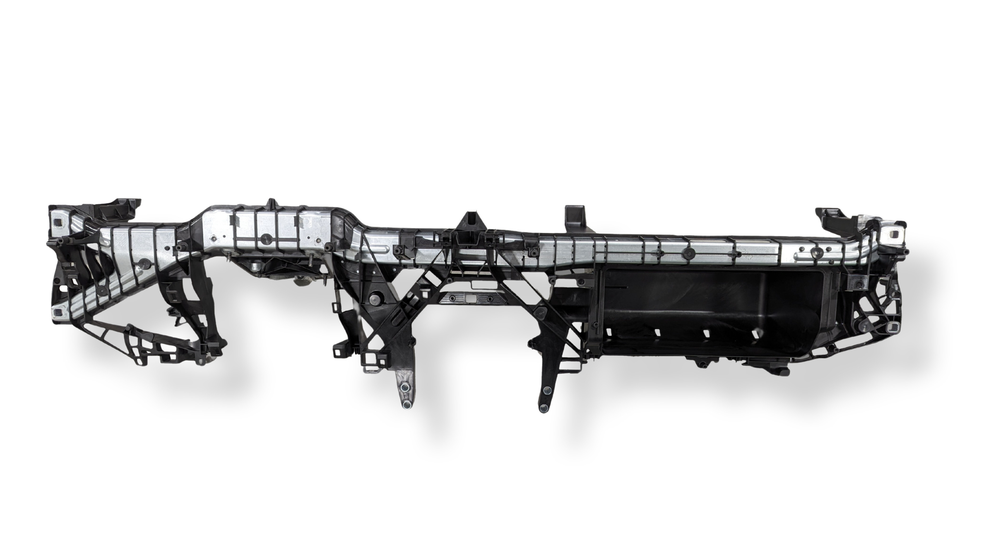

Cross car beam

SPE Award 2024 - 1st place in the category “chassis unit/structural component”

Lucid Gravity cross car beam

Vehicle manufacturer: Lucid Motors

Raw material supplier: AKRO-PLASTIC GmbH

Tool manufacturer: ElringKlinger AG

Machine manufacturer: Engel Austria GmbH

Parts manufacturer: ElringKlinger AG

The instrument panel crossmember plays a central role in the complex world of vehicle design. This component, which lies beneath the surface of the dashboard, is not only crucial to the structural integrity of the vehicle, but also contributes significantly to the safety and comfort of the occupants.

The new instrument panel crossmember combines the functionalities of several components, enabling considerable savings to be made. Thanks to the integration, 26 vehicle-specific parts (such as glove box, module holder and frame) and 18 metal nuts could be saved by direct bolting. This simplification reduces weight and creates additional installation space. The material selection of a steel profile in combination with carbon fiber-reinforced polyamide 6, AKROMID® B3 ICF 30 black (5119) and thinner wall thicknesses reinforces this effect. Compared to a system made of PA6-GF 60, the weight of the individual component was reduced by 1.38 kg. Overall, the integration saves 3.5 kg, which corresponds to a weight reduction of 50% compared to a conventional design with a steel cross member.

Environmentally friendly vehicle production

The use of recycled carbon fibers significantly reduces the ecological footprint of the material. The saving of 26 vehicle-specific parts made of metal and plastic significantly reduces the consumption of resources. In addition, the system weight reduction of 3.5 kg contributes to the optimization of vehicle operating costs.

Image dimensions not found

Change image or reupload it

Sustainability & efficiency

For greater energy absorption in the event of a crash, we have integrated specific predetermined breaking points that enable a controlled collapse. Dedicated restraint elements prevent add-on parts from being detached in the event of a collision. Even the glove box contributes to safety thanks to the direct connection of the knee airbag.

Although the integration of the various functions increases the complexity of the component and the injection mold, our innovative mold and machine concept enables fully automated production. The stamped steel inserts are positively positioned in the tool and fixed in place by overmolding. This reinforces the C-profile and increases the vibration resistance in the area of the steering column and screens (48 - 51 Hz vibration resistance).

Show more

New benchmarks

Lucid Motors is setting new standards in vehicle design with its innovative instrument panel cross member. By combining high functionality, improved safety, weight reduction and cost efficiency, the company is revolutionizing the vehicle interior and thus creating added value for manufacturers and end users alike.